Manufacturing

There are very evident EHS risks, as well as potential environmental and social impacts for manufacturing organizations and their surrounding communities.

Our compliance with international standards

Meet your EHS, ESG, quality, and compliance requirements

Crucial solution modules

Risk and Control Management

Inspections

Observations

Actions

Environmental Sustainability

Incident Management

Audits

Social Sustainability

ESG Reporting and Management

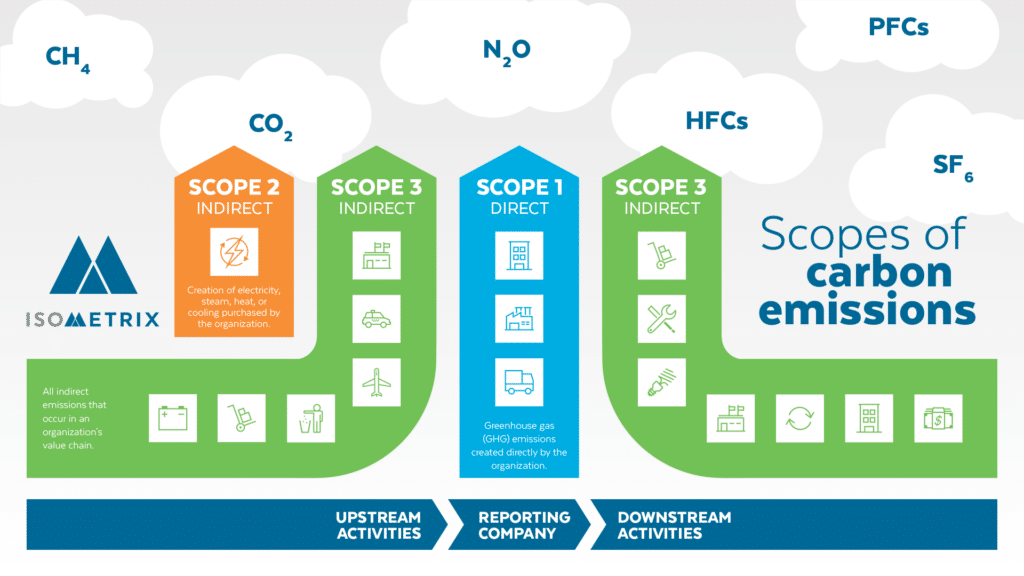

Scope 1, 2, and 3 emissions

Want to see if our EHS management software is for you?